One of the biggest challenge leadership faces is predicting future or lets also say even to understand current state of project. Though while using Kanban, you make things visual and we have flow(though it may change/improve as you progress) but one still needs few visual reports. Lets see how they can be of some help.

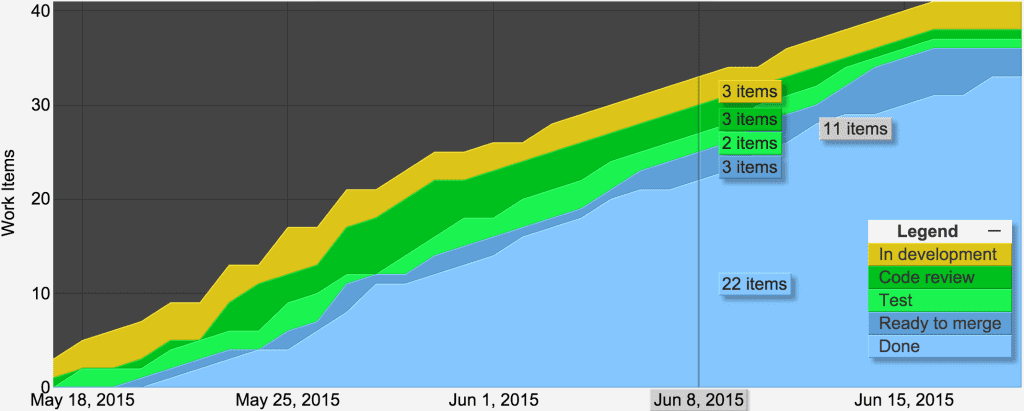

Cumulative flow Diagram shows how work “accumulates in flow” with time. It shows the relative amount of work for each stage of project over the time.Large gaps and flat horizontal lines indicate impediments to flow or lack of flow, which usually occur due to irrelevant work in progress limits.

In the example above, on the 8th June 2015, there were 22 items in Done, 3 items in Ready To Merge, 2 items in Test, 3 items in Code Review and 3 items in In Development.

Similarly on 15th June 2015, there were 30 items Done, 5 items in Ready To Merge, and only 1 item in Test. Which means there is some impediment at Test level, which is drying up work at Ready to Merge state.

Lead and Cycle Time Report presents the average amount of time it takes for a task to be processed from the specific start to the finish point. Depending on the economic value you choose to measure, both cycle time and lead time can be applied directly to your team. For example, if you want to improve the delivery capabilities of your software development team, your cycle time measurement can track the time it takes a work item to go from the commitment point to deployment.

Throughput is the average number of units processed per time unit. In a Kanban system, examples can include “cards per day” or “story points per iteration”.Throughput is important to track to know what impacts your economic system. Think about how an understanding of the average units processed per time period impacts business decisions and measure it accordingly.

Little’s Law shows how an increase in WIP can lead to an increase in the expected cycle time.

C = λ/W

Where

C = Cycle Time

λ = Work In Progress (WIP)

W = Average Completion Rate

For example, if a team has 40 cards and a throughput of 2 cards/day, then the average cycle time is 20 days. If the same team maintains the same throughput but increases its total WIP to 50 cards, the average cycle time becomes 25 days. Little’s Law can be a powerful demonstration of how reducing WIP can reduce cycle time, which is often a valuable business benefit.We could also improve cycle time by increasing throughput, but increasing a team’s throughput is often more difficult in practice than reducing the total WIP.Which ever reporting pattern we use, at end the goal is more about creating economic value than it is about having the fastest cycle time or highest throughput. Maintaining a steady flow of work through your Kanban system can help you deliver value more quickly and reliably.